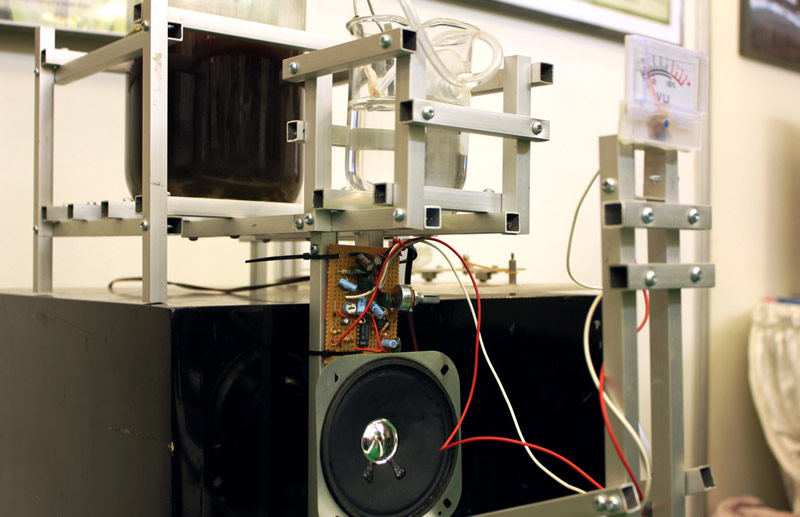

Intelligent Bacteria is one of the research program in the Education Focus Program (EFP), which focuses on the collaboration between art and science. This program is the result of collaboration between HONF and a scientist community from the University of Gajah Mada (UGM) to explore the field of microbiology and biotechnology. Intelligence Bacteria have a main goal to bridge the practice, theories and innovative ideas from the fields of art and science to actualize it’s application based on generic infrastructure and affordable technologies. This platform was built from a common vision to develop and integrate the two fields of disciplines to find new forms of innovation which refers to the needs of interdisciplinary actions for the wide society.

Research I

Saccharomyces Cerevisiae

Fruit Fermentation

May 2010 – July 2010

HONF Lab, UGM Microbiology Lab

Fruit Fermentation Video Tutorial from Julian Abraham on Vimeo.

BASIC THOUGHT

Based on the mass media in the past two months, numerous victims have died in vain due to unfortunate self-made alcohol drinks. Directly or not, this phenomenon occurred post the announcement of new regulation from the Ministry of Financial Department (PMK) No.62 of 2010 date 17/03 (Peraturan Menteri Keuangan (PMK) No.62 tahun 2010 tanggal 17/03) about the increasement in excise duty on alcohol. This regulation directly triggered expensive price in retail selling of alcohol drinks in the early of April 2010. Whereas the market segmentation of local traditional alcohol drinks is addressed to the diversified community low-middle economic community.

This phenomenon is mainly caused by the new regulation are causing the price of local produced alcohol drinks are unaffordable by the society. For example, the price of one bottle of Red Wine “Orang Tua” brand before the regulation was Rp. 15,000.00. After the new regulation, the price went up triple times as much as Rp. 45,000.00.

Self-made alcohol drinks in the market, in fact contain very dangerous substances. Research results from Forensic Laboratory of Kudus City Police Department in analyzing the self-made alcohol that caused the death of three people in Kudus last April, shows an amount of Methanol substance inside the drinks (Folnews.com). Based on the explanation from researchers at Microbiology Department of Gadjah Mada University (UGM) of Yogyakarta, Methanol substance inside the drinks are likely caused by unfavorable fermentation in the production. The type of alcohol produced from fermentation process that can be safely consumed in a certain amount is Ethanol. Unhygienic fermentation process can caused bacterial contamination causing Methanol to be produced as the alcohol product. If Methanol constantly consumed in certain amount of time, it can caused vision disorder to blindness, and even death.

The containment of Methanol produced from the producing of self-mad alcohol drinks by the society is mainly caused by the lack of knowledge from the society in the proper fermentation process. By these reason, HONF collaborate with researchers at Microbiology UGM Yogyakarta to conduct a research in introducing a proper and safe fermentation technology for the society. Hopefully, this technology can be used by the society in producing self-made alcohol that is safe for consumption.

FOCUS

Fermentation is a process of energy producing by microbes through the sugar molecules splitting in an anaerobic atmosphere. Anaerobic atmosphere is an atmospheric situation which Oxygen (O2) are not available in the area. In alcohol fermentation process, the microbes are commonly used is called Saccharomyces cerevisiae. In the process, Saccharomyces cerevisae will convert Sugar in to alcohol (Ethanol) and CO2. CO2 gas will be released in to the atmosphere, while alcohol (Ethanol) will remain in the container where the fermentation took place (Fermentor).

Normally, fermentation process lasts for 10 – 14 days, and the percentage of the alcohol (Ethanol) produced is less than 15%. This can be caused by many factors such as sugar content, room temperature, microbial properties, material density, water activities etc. Basically the main ingredient of the fermentation is the amount of sugar inside the fermentation materials. Thus, any material containing sugar can be used as a fermentation material.

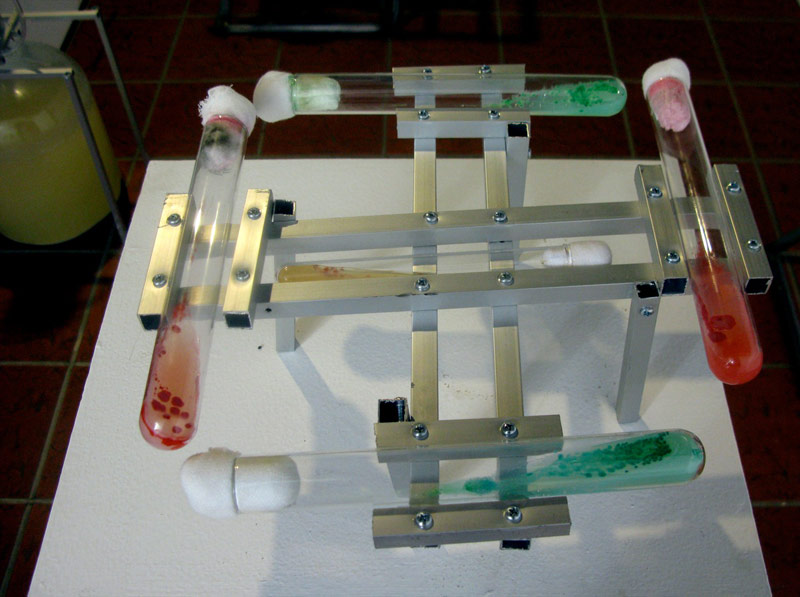

Taste, flavor, and of course alcohol content (Ethanol) that is produced are dependable on the type of fermentation materials. In this research, HONF and UGM Microbiology Laboratory have tried several types of fruit as fermentation materials to evaluate the differences in taste, aroma, alcohol (Ethanol) grade that is generated and also production cost of the fermentation itself. Fruit that has been used as test subjects for fermentation materials are Pineapple, Chrysophyllum, Palm water, Salak, Mango and Soursop.

INGREDIENTS

1. Water: used in the research is boiled mineral water

MINERAL WATER is best. Some city water with excessive chlorine should be boiled (if not filtered), in order to drive off the free chlorine. Distilled water is not recommended (no minerals) and a rule of thumb is; if it tastes good, then use it (taste your water in a warm condition because cold temperature masks the taste of water). WATER does AFFECTS the TASTE RESULT OF WINE.

2. Fermentation Materials, Fruit

Fruits contain sugar (glucose, fructose, and sucrose). Basically the main ingredient for the fermentation process is the amount of sugar inside the fermentation materials. Thus, any fruits/roots/ containing sugar can be used as a fermentation material. FERMENTATION MATERIALS AFFECTS TASTE, FLAVOR, and ALCOHOL CONTENT (ETHANOL) of your WINE.

Fermentation materials that has been used in this research are:

- Ananas comosus (L.) Merr. (Nanas [id] or Pineapple [en]);

- Arenga pinnata (Aren [id] or Sugar Palm [en]);

- Salacca zalacca (Salak [id] or Snake Fruit [en]),

- Mangifera indica (Mangga [id] or Mango [en]),

- Annona muricata L. (Sirsak [id] or Soursop [en]);

- Artocarpus heterophyllus (Nangka [id] or Jackfruit [en]);

- Cucumis melo L. (Melon [id/en]);

- Tamarindus indica (Asam Jawa [id] or Tamarind [en]);

- Zingiber officinale (Jahe [id] or Ginger [en]);

- Manilkara zapota (Sawo [id] or Sapodilla [en]);

- Citrullus lanatus (Semangka [id] or Watermelon [en]);

- Musaceae (Pisang Klutuk [id] or Banana [en]);

- Citrus (Jeruk [id], Orange [en]);

- Malus domestica (Apel [id] or Apple [en]);

- Solanum lycopersicum (Tomat [id] or Tomato [en]);

- Sorghum bicolor (Sweet Sorghum);

- Cucurbita spp. (Labu [id] or Pumpkin [en];

- Pachyrhizus erosus (Bengkuang [id] or Jícama [en])

- Ipomoea batatas L. (Ubi Jalar [id] or Sweet Potato [en])

3. Sugar (additive material): used in the research is white sugar

Most fruits as mentioned have natural sugar in them and without adding extra sugar, these can be turned into a wine of about 4% to 6% volume alcohol. This is a low alcohol content and the wine will not keep for long, although it could be drunk young. Most home wine makers prefer to make a stronger wine of about 12% to 17%, so sugar is needed to bring alcohol content up to a level high enough to store longer. SUGAR ALSO AFFECTS THE TASTE OF WINE. The research also experiment in different amount of sugar as an additive material to get different taste and alcohol content from the wine.

A tool called hydrometer could calculate the amount of sugar required and give sweetness value from the wine sample. If the hydrometer reads 990, then the wine sample will become a dry wine and it will require more sugar to have better sweetness in the taste. If the hydrometer reads 1020 then it will be a sweet wine. It will require several hydrometer measurement while fermentation process occurred to test whether addition sugar is needed to get the desired taste and alcohol amount in the wine. Ideally it will require 1 kg of sugar per gallon (4.5 liters) of wine. Without a hydrometer, fermentation process will have to rely on guesswork and experience of the winemaker. If the wine is too sweet, less sugar additive should be used in the next batch. If the wine is too dry, then more sugar in the next batch will be needed.

4. Yeasts: used in the research is Saccharomyces cerevisae from Microbiology Laboratory Faculty of Agriculture, Gadjah Mada University Yogyakarta

YEAST is a MICROSCOPIC MICROORGANISM that CONVERT SUGAR into ETHANOL and CARBON DIOXIDE GAS. THIS PROCESS is called FERMENTATION. Once the alcohol content in the wine is reach a high level, it will kill off the yeasts. If you have added a lot of sugar and the alcohol level kills off the yeast before all the sugar is converted, then you will end up with a sweet wine. If the sugar amount is enough and all the amount are converted to alcohol, you will produce a dry wine. A tool called Wine Hydrometer can tell you the specific gravity of your wine (how much sugar remains in the liquid) and therefore give you a calculation on how much sugar to add for the desired sweetness.

Wine yeasts can be straightly added into the fermenting bin, but it is better to start them off in some warm fruit juice (the juice from fruits is ideal) and then add it to the fermenting container once the yeast is bubbling. Yeast is found naturally in the bloom of grapes, so we can create our own yeast by crushing a few grapes into some warm natural fruit juice. Orange juice works well. Once this is bubbling, add it to fermenting bin.

STERILIZATION & SANITATION

To make a great wine, a clean and sterile fermentation process is a must. It is ABSOLUTELY NECESSARY to keep everything (all equipments including our body parts) that came in touch with the fermentation process CLEAN. REPETITIVE SANITATION process is needed if we are not sure whether the equipments are sterile enough to use for the fermentation process. This is a crucial process in wine making as a failure to create CLEAN working space will results all of the time, money and energy spent a total waste.

UNCLEAN equipments and environments in wine making will cause bacterial contamination. Bacterial contamination caused acid production and/or METHANOL and other undesired compounds. METHANOL is DANGEROUS FOR HUMAN CONSUMPTION. METHANOL CAN CAUSE BLINDNESS AND EVEN DEATH IF IT CONSUMED IN A HIGH AMOUNT AND/OR CONTINUOUSLY BY HUMAN. The maximum amount of 2% Methanol volume per volume (v/v) can be consumed by human in healthy condition.

Bacterial Contamination could caused by:

LACTIC ACID BACTERIA

- Lactic acid bacteria (LAB) are responsible for many fermented foods such as sauerkraut, pickles and yogurt. They have also been isolated from wines at various states of vinification. In wines they are responsible for malolactic fermentation (MLF) which can be beneficial in some cases and undesirable in others. Besides conducting MLF, these bacteria under certain conditions can also CAUSE undesirable changes in wine FLAVOR which renders the WINE UNDRINKABLE. Many species of LAB do not conduct MLF and their growth in wine can cause some serious wine spoilage. LAB is most likely to occurred in an UNCLEAN fermentation process. Lactic Acid bacteria found in wine belong to three genera, namely:

- a. Leuconostoc – Heterofermentative coccus, oval or spherical, occur in pairs or chains.

- b. Pediococcus – Homofermentative coccus, often found in tetrads.

- c. Lactobacillus – Homofermentative or heterofermentative rods, found singly or in chains.

METHANOL PRODUCING BACTERIA

Methanol is found naturally in the environment. Bacteria living in anaerobic surrounding produce methanol as a waste stream. Other bacteria also living in anaerobic conditions will use methanol as a food and produce methane. These bacteria are the same bacteria found in septic tanks and anaerobic digesters used by farmers and wastewater treatment plants. Several species of bacteria that capable contaminate fermentation process and produce methanol are:

- – Enterobacteria: such as E. coli and Salmonella

- – Enterococcus: such as Enterococcus faecalis

- – Micrococci: such as Staphylococcus

- – Erwinia carotovora

- – Zymomonas mobilis

There are several products that could be used for sanitation process in wine making:

98% Ethanol

This is the most easiest product that available in any chemical laboratory shop. It is handy, affordable and easy-to-use makes it a very useful in the fermentation process. Place Ethanol to a sprayer and it can be used for sanitizing hands, joints and other delicate surfaces.

Chlorine (household bleach)

- Bleach (non-scented) is a cheap and an effective disinfectant and cleaner. Two ounces in 5 gallons of water and an overnight soak will clean your glass fermenter. 1/2 teaspoon to 1&1/2 teaspoon in 5 gallons of water with 1/2 to 1 hour soak will sanitize. Also, 1 1/2 ounces per gallon is good as a sanitizing sponge wash with three hot clear water rinses. It is very useful to be used for washing glass equipments for the fermentation process.

- Warning: Chlorine is CORROSIVE to STAINLESS STEEL, COPPER, BRASS, and it’s not too good for your SKIN.

Boiling

Sanitation could also achieved by boiling the equipments for fermentation process. Don’t boil plastic equipment as it may deform and become useless. Brew water also can be sanitized by boiling and it is mandatory (if it’s not filtered). Boiling brew water will get rid of the chlorine, but this process also get rid of oxygen. As Yeast need oxygen during the first 24 hours of fermentation, boiled water needs oxygen by vigorously stirring the air back to the water before use).

Don’t ruin sanitizing process by drying off equipments with some dirty towel. Sanitize working area and let equipments air dry (or use it wet), rather than using unclean fabrics to dry it of. Keep cats, kids, canaries, canines, and other animal annoyances outside the working area. Always keep doors and windows shut to avoid airborne bugs, dusts and microscopic creature from the working space.

EXHIBITION / PRESENTATION / WORKSHOP

Intelligent Bacteria – Saccharomyces cerevisiae have participated several exhibition in Indonesia in the past such as:

- FIXER | Pameran Ruang Alternatif & Kelompok Seni Rupa di Indonesia (link to event)

Exhibition at North Art Space Jakarta, 18 – 28, June 2010

Intelligent Bacteria – Fixer – 2010 from Julian Abraham on Vimeo.- Nu-Substance 2010 – “The Loss of the Real” Art Exhibition (link to event)

Exhibition at Selasar Sunaryo Artspace Bandung, 19 July – 1 August 2010

- Festival Kesenian Yogyakarta XXII 2010 (FKY XXII 2010) (link to event)

Exhibition and Workshop at Vredeburg, Yogyakarta, 27 June – 7 July 2010

- Research Week UGM | Gadjah Mada University 2010 (link to event)

Exhibition and Presentation at Grha Sabha Pramana, Yogyakarta, 12 – 17 July 2010

- cellsOPEN | Cellsbutton#04 – Yogyakarta International Media Art Festival, 2010 (link to event)

Exhibition at 7Soul Distro, Yogyakarta, 27 July 2010